1. [left] An Elizabethan ‘show–off’ house of 1603, now The Feathers Hotel, Ludlow. Very

attractive iron fixed lights and outward opening casements, but desperately ‘leaky’.

2. [right] Typical iron casement with leaded lights and saddle bars (the three horizontal

bars) to keep the glass from blowing in. This example is from Abbot’s Hospital in Guildford,

built in 1619–22 by the Archbishop of Canterbury to shelter twelve elderly men and eight

women. Coincidentally, it later housed the Duke of Monmouth (see Note 1) — under

guard on his way from the disastrous Battle of Sedgemoor to his execution in London.

We left Sir Balthazar Gerbier, at the end of Part 1, speaking rather slightingly (in 1662) of our English metal casement window [1,2] and its poor performance in the field of unwanted air infiltration. Born in Holland of French Huguenot extraction, he had settled in England at an early stage in his life. He had travelled as a diplomat and courtier throughout Italy, France, Spain, and Germany, in all of which he would have seen wooden casements, in some cases doubled–up against adverse weather conditions [3,4]. Wooden casements existed in England at that time but were unusual, and were apparently not made with the same degree of careful detailing as the continental examples that Gerbier and other travellers had noted; even as late as the middle of the nineteenth century John Claudius Loudon (the prolific Scottish writer on all things agricultural and architectural) was suggesting the adoption of the continental casement meeting stile detail [5], which was designed, by its interlocking nature, to ensure a greater degree of air–tightness. In a well–constructed window of this type the gaps between the casement and the frame could be reduced to an absolute minimum (i.e. actually touching), with only a small gap at top and bottom needed to allow smooth operation. Additionally, continental security fixings were such as to force the opening light under pressure against the frame, thus further reducing unwanted air movement.

3. [left] An example of doubled–up casements at the restored Chateau Karlova Koruna, Chlumec,

Bohemia. Note the security grille in the gap between inner and outer casements; exactly how the

external casements were cleaned is not revealed. 4. [centre] In spite of the very visible

security arrangements the windows sit comfortably in these ‘polite’ surroundings. 5. [right]

Loudon’s detail, adapted from his Encyclopaedia of Cottage, Farm, and Villa

Architecture, and Furniture 1846.

ENGLISH SECONDARY GLAZING

Conversely the sash window [6] has always needed gaps around all sides of each sash in order to function properly, with consequent disadvantages, as John Nicholson pointed out to carpenters and joiners ‘and workmen in general’ in his New Carpenter’s Guide (1828):

The sashes which are fixed should be quite tight; but those which are to be hung should be made to move, slide, or shut, easily, without having too much room to work in, otherwise the stream of air which presses through the joints being too great will render the room very cold in winter.

During Gerbier’s lifetime (1592–1663) there had existed in England horizontal sliding windows [7] in wood — developed from medieval sliding shutter boards — needing just as much ‘play’ in their construction as the later vertical sliding windows would require. These, together with the relatively few wooden casements in existence, might be glazed with glass quarries in lead (‘leaded lights’) or later with wooden glazing bars (metal casements always had leaded lights — there was no other way of fixing the glass panes). At that time the concept of secondary glazing involved fixing oiled or varnished paper to the window glazing bars, where they existed, or inserting a removable paper–covered wooden frame into the opening.

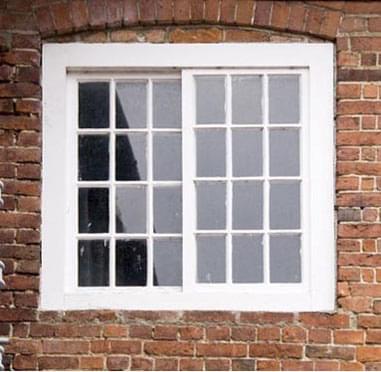

6. [left] A page from the New Carpenter’s Guide. 7. [right] A typical horizontal sliding sash window,

known generally as a ‘Yorkshire’ sash, having one light fixed and the other moving.

However, an example exists at Ham House, Surrey, of an original 1610 metal casement window with a later secondary glazing arrangement of inward opening wooden casements [8], a more sophisticated solution. It is clear from the configuration of frame and window opening that these (and others elsewhere at Ham) were, in modern jargon, retro–fitted; and it can be deduced that their main purpose was to keep out draughts from the fact that in almost all cases the secondary glazing is easily removable and is generally applied only over the opening metal casements and not the fixed lights. The Orangery at Ham [9], built in the 1670s, has metal casements fixed on both the inner and outer faces of the wall [10] with an air gap between; again, their location is selective, being applied only where there are opening casements and so the arrangement cannot be regarded as true double–glazing.

8. [bottom left] This pair of casements could have been added at any time, but the thickness of

the glazing bars suggests an earlier rather than a later date. 9. [top] The Orangery at Ham House,

Surrey; here the secondary glazing has been applied to full height of the windows but no precautions

have been taken in the case of the doors or the lights over. 10. [bottom right] The full–height

inner casements can be easily seen.

ROYAL PROGRESS

The development of the sash window gained its impetus from a number of sources — the return from exile on the Continent of Charles II and his courtiers, influenced by what they saw there; the Great Fire of London, with the consequent major rebuilding programme and introduction of new Building Regulations; the decline of the City of London guild system, leading to the introduction of foreign carpenters and joiners to cope with the work, many with more advanced skills than their English counterparts; improvements in glass technology (some of which were ‘stolen’ from the French); the eventual importation of better quality timber from abroad and improvements in woodworking tools and machinery; and the emergence of rational and scientific thought, as exemplified by the formation of the Royal Society in 1663. Fashion was also, as always, of paramount importance. The rich were building large houses in the country and were in strenuous competition with one another in copying the King — it would be amusing to talk of keeping up with the Inigo Joneses but this would be entirely misleading, as Jones himself was of the old school where windows were concerned, preferring to stick with casements, albeit the comparatively rare wooden variety. This headlong copycat dash into the new window technology led to some early failures; often the craftsmen employed were unfamiliar with the techniques of construction, and there are examples of joiners being sent from Scotland to London to be re–trained in the new mode. Initially, few could afford sash windows of the size that Charles II was having made by the Office of Works in the 1680s for the Palace of Whitehall, being as much as 14 feet (4.25m) high by 6 feet (1.8m) wide (see also Note 1 on this subject).

‘GUILLOTINE’ WINDOWS

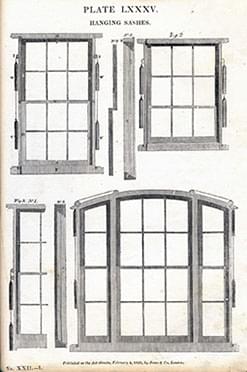

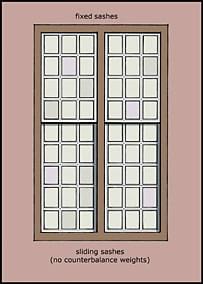

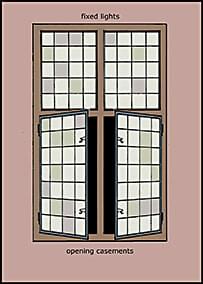

But we need to go back a stage. Earlier in the seventeenth century the forerunner of the sash window [11], imported from France, had been based on the appearance of the standard timber ‘cross’ window [12], the outer frame and central mullion of which performed a structural function. The top sashes were permanently fixed, and the lower sashes had to be lifted into position and retained there by pegs, an inconvenient and potentially dangerous system [13], but to increase the ventilation or see out of the window (early glass was not exactly crystal clear) that is what you had to do. In France these had been developed because in narrow staircases or constricted areas inward–opening casements could be inconvenient or dangerous. Because English casements always opened outwards this difficulty never arose. The name ‘guillotine window’ was coined half a century later following the ‘invention’ by Dr. Guillotin during the French Revolution of the infamous decapitation machine (which however he based on pre–existing English models such as the ‘Halifax Gibbet’). The term is still in use in France and Quebec, and in the United States — regardless of the fact that a counterbalanced sash window is perfectly safe.

11. [left] Typical early ‘mullioned’ sash window. 12. [centre] Typical mullion and transom, or

‘cross’ window, from which the earliest sash windows were derived. 13. [right] An example of an

early sash window from a museum in Antwerp; its exact purpose is unknown; it is internal and serves

to provide ‘borrowed’ light, and to act as some sort of serving hatch, or even perhaps as an occasional

acoustic barrier. The metal pegs for holding it in position when open are clearly seen, as are the

turned lifting knobs.

ENGLISH COUNTERBALANCE WEIGHTS APPEAR . . .

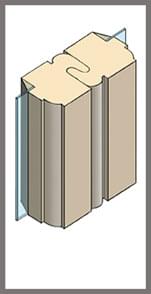

Eventually, in the English version, these mullioned sashes — pairs of vertically sliding sashes either side of the central mullion — were provided with counterbalance weights for safety’s sake; in the early days these would be located on one side of each sash only, either with both weights in a groove hollowed out of the outer frame, or both at the centre in grooves formed in the mullion. This one–sided operation was feasible only because the sashes were narrow enough to slide up and down without racking (tilting over to one side and jamming). The grooved frames and mullions eventually developed into purpose–made boxes, hence the English term ‘box sash’ (or in Scotland, ‘cased frame’) to describe the whole assembly. It could be argued that the introduction of this novel early ‘health and safety’ measure constitutes the defining moment in the genesis of the modern sash window.

Existing mullion–and–transom or ‘cross’ windows were sometimes adapted and made into mullioned sash windows as described above. In these cases, the use of timber prone to movement and combined with the site manufacture of sashes (rather than in the relatively controlled environment of a joiner’s workshop) would have resulted in greater tolerances than were desirable. Perhaps because of this there was a move, in the early stages of the rebuilding of the Royal Palaces following the restoration of the monarchy in 1660, to double up windows. This was probably generated more by considerations of excessive air movement than by notions of the insulation value of two skins of glass with a still air pocket between them i.e. true double–glazing. By the 1670s the mullion–and–transom casement window had reached the limit of its potential for technological development, and we may imagine that there was in any case a new spirit of experimentation abroad. As Wren once observed about craftsmen ‘ . . . our English Artists are dull enough at Inventions, but when once a forreigne patterne is set, they imitate soe well that commonly they exceed the originall’.

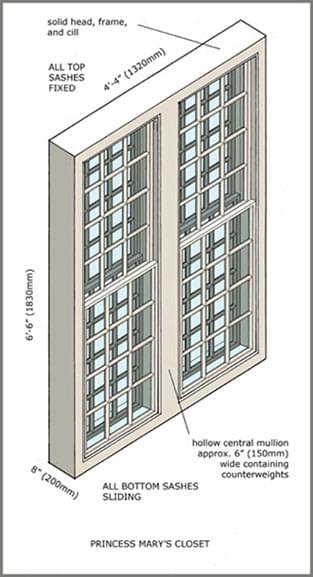

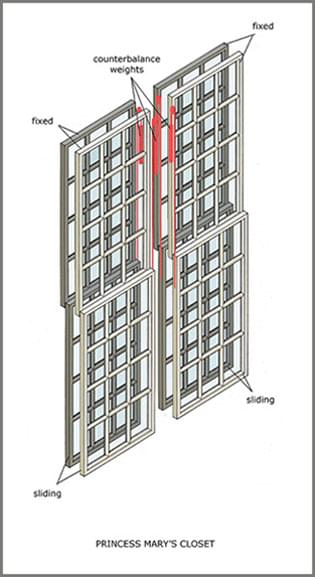

The very extensive, detailed, and scholarly work (on which a good deal of the foregoing is based) carried out over a number of years by Hentie Louw and Robert Crayford enables us to take a close look at an early weather exclusion experiment, and at the same time to understand the why secondary glazing in the form of doubling–up was not very extensively adopted in this country. Louw refers to the period 1660 to 1675 as the ‘Period of Exploration and Invention’, when the Office of Works was employed at Whitehall and St James’s Palace. It has been possible to reconstruct the doubled–up mullioned sashes of Princess Mary’s Closet at St James’s Palace [14] from drawings published by Louw and Crayford. The workings are shown at [15]; it will be seen that there are effectively four single–hung sash windows, a pair side by side on the inside of the building and another pair on the outside within the same overall frame, all bottom sashes being operated by one counter–balancing weight each (highlighted in red) concealed within the centre mullion of the window.

14. [left] Inside view of the mullioned sashes of Princess Mary’s Closet, St James’s Palace, 1672.

It is unlikely that this window would have been brought on site complete, as shown. At that date it is

probable that the joiner would have installed his prefabricated sashes in a structural frame provided

by the carpenter. [After Louw and Crayford]. 15. [right] Inside view: the internal workings of the

window. [After Louw and Crayford].

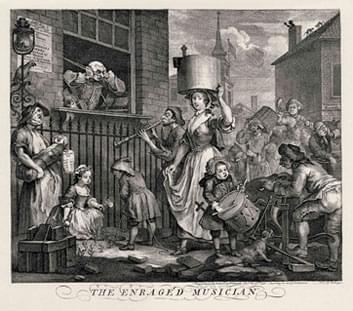

As the top sashes are all fixed, window cleaning becomes a problem — and can only be achieved by taking out one of the fixed top sashes temporarily. Furthermore the view through the window would have been severely compromised by the profusion of glazing bars [16], and by unevenness and colour variation in the glass. All in all the experiment must have been regarded as a failure. Apart from the doubled cost and the loss of light the reduction in air movement was probably only marginal; one benefit could have been a reduction in sound transmission but this is a technical aspect of window design scarcely, if ever, mentioned in the building–related documents of the time. This is odd, as there are constant references in eighteenth century literature and prints to the very high levels of noise from wheeled traffic running on cobbles, street vendors, and street musicians [17].

16. [left] The result of doubling–up the sashes would have been reduced visibility and a darker room

due to the second layer of thick glazing bars. As glazing bars decreased considerably in size as time went

on, this defect would have become less noticeable; nevertheless single glazing has remained the norm to

this day. 17. [right] Hogarth’s engraving ‘The Enraged Musician’ needs no explanation.

ANOTHER STEP FORWARD . . .

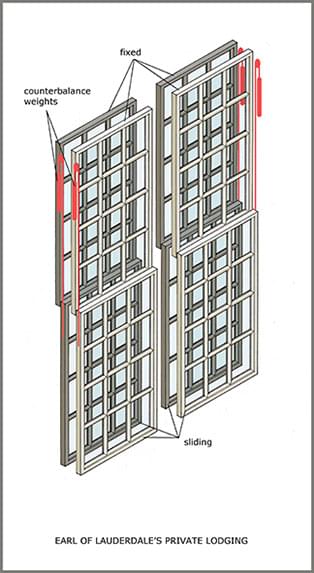

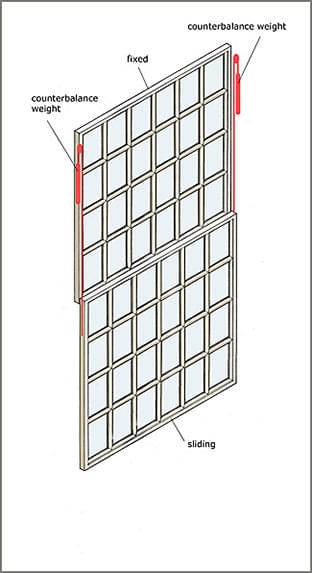

At the same time as the windows of Princess Mary’s Closet were being installed an almost identical window was being installed in the Earl of Lauderdale’s private lodging at Whitehall Palace, but this time with the counterbalance weights located in the outer frame, and again with one per sash. Although in this particular example the central mullion was thus freed up from its role as accommodation for the counter–balance mechanism, habit and tradition dictated that it should remain looking exactly like the mullion of the cross window from which it was derived. In fact it was very little different in size from that of Princess Mary’s Closet; the need to match adjacent unmodified existing cross–windows could well have been a factor in reaching this decision, however. Looking at the mechanism stripped of its frame [18], it is easy to see the benefit of combining the two side–by–side sashes into one [19], and at the same time halving the cost by omitting the by then discredited secondary glazing component. The earliest recorded date for this type of window is around 1673, when the architect Robert Hooke installed six large windows each consisting of two sashes, the top fixed and the bottom sliding vertically, at the College of Physicians in London.

18. [left] Inside view of the mullioned sashes of the Duke of Lauderdale’s Lodging, Whitehall Palace,

1673. The counterbalance weights have moved to the outside but the central mullion (not shown),

now redundant, remains. [After Louw and Crayford]. 19. [right] Inside view of the obvious

development from the mullioned sash, once the weights had moved to the outside, and the model

for all subsequent sash windows.

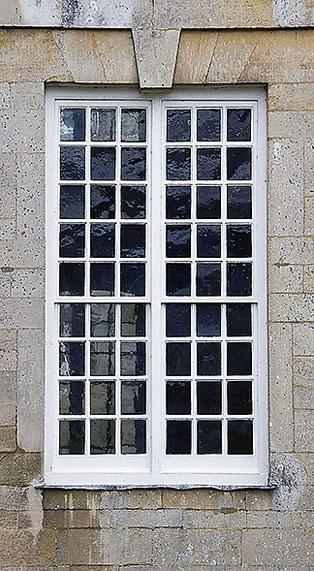

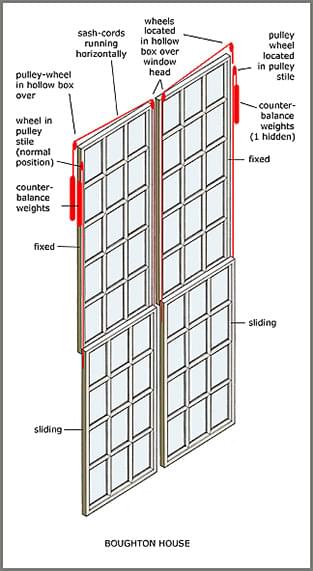

An example of this early mullioned sash window type is still in existence at Boughton House in Northamptonshire [20], although in this case central mullion has been reduced to something like the minimum practical width. When investigated by Louw and Crayford it was found that it represented a transitional stage, in that each of the bottom sashes was operated by two sash cords and weights, the inner cords being taken to the outside of the frame over the head of the window [21]. The later practice of making the formerly fixed top sashes slide down so as to create an air gap at the head of the frame brings us ultimately to the modern sash window, the basic mechanism of which has remained unchanged for nearly three and a half centuries.

20. [left] Very early mullioned sash window at Boughton House, Northamptonshire. 21. [right]

Inside view of the window showing how the weights lie side by side as in a modern sash window,

but operate only the lower sashes. [After Louw and Crayford].

AND A STEP BACK . . .

One consequence of creating this double–hung sash (with both sashes able to slide up and down freely — required by law from 1858) was that the air gap between the sash and the frame was now practically doubled in area, the top sash having been fixed ‘quite tight’, in Nicholson’s words, and then the joints painted over. This extra gap had the effect of increasing the levels of air infiltration and exfiltration — in other words giving rise to the draughty living rooms and bedrooms for which English homes became notorious throughout the rest of Europe. In The English House Hermann Muthesius, a German social historian and architect living in England at the beginning of the twentieth century, describes ‘the local determinants of the English house’ :

. . . the English climate is fundamentally different from that of the continent; in particular it is milder, the air is extremely damp and it is generally inhospitable . . . The mildness and evenness of the climate account for the insubstantial structure of the English house, especially the meagre thickness of the walls, the absence . . . of double glazed windows, the negligible care bestowed on ensuring that windows and doors fit snugly . . . Open fires are the only means of heating the house. The advantages the fireplace is deemed to possess . . . so completely convince the Englishmen of its superiority to all other forms of heating that he never even remotely considers replacing it with the more efficient and more economical stove. However, the fireplace in England serves another, extremely important, purpose . . . ventilation. Much ventilation is needed, largely because of the high humidity of the atmosphere . . . it accounts for the frequent fogs, for the distances in which all is veiled in a light mist, for the luxuriant green of the plant life, which lasts the whole year round . . . In enclosed spaces it induces the fusty, musty smell that affects any room that is not thoroughly ventilated every day. It necessitates extremely powerful ventilation, which, indeed, the fire–place admirably provides. The need for ventilation . . . accounts for the Englishman’s fondness for sash–windows . . . the large amount of ventilation is the cause of the famous draughtiness of the English houses, which has already provoked many a harsh word from foreigners.

He goes on to observe ‘that the blazing fire in the grate is responsible for continuously sucking a powerful current of air through cracks in doors and windows, towards the fire–place’, but that the English are ‘more or less impervious to the draught . . . because they take the precaution of wearing warm underclothing’. Warm clothes had always been a sensible precaution against the cold, and perhaps we should nowadays take greater advantage of them, and follow the example set by the Emperor Augustus, who we met in Part 1, or even our own ancestors [22].

Readers of a certain age will remember the days before central heating when, sitting in front of a blazing fire, an icy draught would be felt on the back — the reason for the existence of the high–backed, winged, armchair and in country pubs, the settle [23]. Internal shutters could be closed, but seldom were, because many were ‘painted shut’ and therefore inoperable — for some reason the use of these went out of fashion. Heavy curtains could be drawn across the window (and the door, if a portiere rod was in use — a device for lowering the curtain to cover the gap below the door as it closed), very effective provided that the fabric was heavy and voluminous enough. Primitive attempts were often made to seal the gap at the bottom of a door by laying a roll–shaped cushion against it. External doors were sometimes ‘protected’ by a relatively ineffective strip of folded copper known, curiously, as ‘Atomic Strip’. As a last resort sash windows were also sometimes painted shut, although it could be argued that this was often more to prevent the windows from rattling than a heat saving measure, the English being ‘more or less impervious’ to cold, as Muthesius observed.

22. [left] Family Group at Tea in the Garden, Castle Acre, Norfolk, c.1890. 23. [right] The settle

provided full height protection against draughts and was usually placed near the fire in a farmhouse

or manorial hall — the forerunner of the porter’s chair of the Georgian period and, we might

reasonably suppose, the winged armchair that is still in use today.

FORWARD AGAIN . . .

The laws of physics don’t make things easy for us — we want to be warm and comfortable, but we don’t want to pay too much for our heat, and have now come to realise that we shouldn’t waste it by letting it escape through gaps in the fabric of our buildings— but we don’t want our homes to be damaged by damp, rot and infestation, which is why good ventilation is essential. Together with these conflicting requirements we have energy–saving Building Regulation legislation that is making, in combination with an unprincipled uPVC double–glazing industry, a potentially very serious assault on our traditional windows — one that could adversely affect the character of our buildings, towns and villages. The English Heritage publication Energy conservation in traditional buildings [24] attempts to counter this.

English Heritage has claimed for many years that unnecessary work should not be carried out to windows in general, and in particular to the windows of listed buildings. This has always been on the basis of heat loss calculations that reveal the poor short–term economic performance of double–glazing in the form of sealed glass units — calculations that were open to criticism from certain areas of the window industry. Now, English Heritage are undertaking a series of laboratory tests on actual windows, and the results of the first in the series have been published; these are tests carried out on a traditional two over two (i.e. Victorian pattern) average–sized double–hung vertical sliding sash window. A window in poor condition was specifically selected in order to demonstrate the benefits of simple repairs alone. It was installed between two environmental chambers (one hot, one cold) and heat–flow tests undertaken ‘as–found’, after repair, and again after draught proofing. The effects of adding curtains, blinds, shutters and secondary glazing were also evaluated, testing also for the adverse effects of insufficient ventilation. The findings of the first report Research into the Thermal Performance of Traditional Windows: Timber Sash Windows [25] are, in essence, that:

1 There are major opportunities for improving the thermal performance of existing windows by relatively simple methods, including traditional curtains, blinds and shutters.

2 There is good potential for improvement from draughtproofing, with air infiltration through the repaired and draughtproofed window being somewhat less than through a standard trickle ventilator.

3 There is potential for further improvement where secondary glazing with a low–emissivity coating is used as well. This gives good performance in the daytime, and better still at night when curtains, blinds and shutters can be used.

CONCLUSION

Whatever our individual thoughts about global warming, it cannot be denied that saving energy saves us money at a personal level; and since so much energy is lost through gaps around windows and doors and in the structure generally why, then, with a couple of thousand years of experience of wind and weather, do we rush off into the waiting arms of double glazing salesmen, assuming that putting two thin sheets of glass together, with a few millimetres between them, is going to solve all our problems? We should always try to retain the power of independent thought. In this way we can look in a carefully considered manner at a range of possible heat–saving measures, including curtains, shutters, blinds, draught proofing, increased roof insulation, more efficient gas boilers and electronic controls, and to think about employing them in a balanced way. Ripping out perfectly good timber windows and replacing them with new of whatever kind cannot be the answer.

Acknowledgements

(All photographs and drawings are by the author unless indicated otherwise)

Picture 17. Private Collection

Picture 22. ©V&A Images/Victoria and Albert Museum, London (www.vam.ac.uk)

Drawings of Princess Mary’s Closet and The Earl of Lauderdale’s private lodging are based on reconstructions by Hentie Louw and Robert Crawford, in Architectural History, The Journal of the Society of Architectural Historians of Great Britain, ‘A Constructional History of the Sash Window’ in Volumes 42 (1999), page 202.